Designing Avnet’s First AI Chatbot: Streamlining Semiconductor Purchasing

Role: Product Owner & UX Collaborator

Duration: January 2017 – September 2017

Tools: Microsoft LUIS (Language Understanding), Excel (data analysis), Lucidchart (flow mapping), Sticky Notes (ideation)

Team: Consulting Partners, Digital Team Leadership, Developers, Customer Service Representatives

Problem

Avnet, a global electronics distributor with over 5 million parts online, faced a flood of inquiries—dozens of calls and hundreds of emails/chats daily—overwhelming its 8-person team and backlogging thousands. This slowed online sales for a firm shipping 30,000+ line items daily to 100,000+ customers.

Goal

Build an AI chatbot—the first in the semiconductor distribution industry—to reduce call volume, streamline the complex purchasing journey, and drive online sales, freeing sales reps for strategic outreach.

Outcome

Launched a pioneering chatbot that cut reliance on customer service, boosted online engagement, and set a new standard for Avnet’s digital offerings across 400 global locations and 800+ suppliers. Jump down to see the results!

Background & Challenge

Avnet, a logistics leader in semiconductor distribution, manages over 5 million parts from 800+ suppliers across 400 locations, shipping 30,000+ line items daily to 100,000+ customers in B2B and B2C markets. Yet, its online platform struggled. Engineers and buyers, facing a complex catalog (e.g., RoHS compliance, multiple manufacturers), abandoned it, overwhelming 8 customer service reps with dozens of calls and hundreds of emails/chats daily, backlogging thousands. This frustrated users and stalled sales.

A 2017 Chicago workshop with consulting partners inspired an industry-first AI chatbot. Unlike simple retail, semiconductor purchasing needed a smart, intuitive tool. Older, less tech-savvy users preferred barebones designs but required pre- and post-purchase support.

The goal: cut calls, save costs, and boost online sales, freeing reps for strategic outreach.

User Pain Points:

Sorting through 5M+ parts with specific needs (e.g., in-stock, preferred manufacturer, delivery date).

Tracking order statuses across a global supply chain.

Resistance to complex or overly modern interfaces.

Business Goals:

Reduce a backlog in the thousands and unlock online sales potential for 100,000+ customers.

Research & Discovery

I kicked off by diving into the customer service crisis. The team shared a raw spreadsheet of call/email/chat types—hundreds of daily interactions distilled into messy data. Using Excel, I sorted and prioritized it, revealing two dominant case types: part searches (e.g., finding a specific quantity from multiple manufacturers) and order status checks. With only 8 reps, the backlog hit thousands, underscoring the urgency.

Interviewed reps to decode their process: they’d query the 5M+ part catalog (mirrored online) with filtering questions—“In stock? RoHS compliant? No EOL notices?”—to narrow options. For orders, they just needed an order number to pull updates (e.g., shipped, in warehouse).

Key insight: Users needed guided help, not free-form guessing, to match this manual flow.

Designed for simplicity, echoing reps’ catalog filtering.

2. Ideation & Flow Design

Armed with research, we brainstormed using hundreds of sticky notes—covering walls with ideas for the chatbot’s scope. I translated these into structured flows in Lucidchart, focusing on an MVP with two core paths: part search and order status. Each flow mapped happy paths (e.g., “Found your part!”) and pain points (e.g., “No stock—try this?”), adding quick feedback prompts like “Did this help?”

Stakeholder sessions with digital leadership, reps, and developers refined these flows. We bucketed ambitious ideas—like cross-selling or returns—for future sprints, ensuring feasibility within timelines.

Tone was critical: friendly, professional, and non-enthusiastic per Avnet’s brand, tailored to our pragmatic users. If flows got too complex, we planned handoffs to reps with full chat context.

Recreated MVP flow, balancing user needs with 5M+ part complexity.

3. Prototyping & Usability Testing

Developers built a prototype in a lower environment, and I led usability tests with real engineers and buyers—some in our offices, others in the field. I crafted scenarios (e.g., “Find a part in stock”) and let them explore freely, observing where they stumbled. Early feedback was brutal: open-ended inputs confused users, especially with 5M+ parts at play.

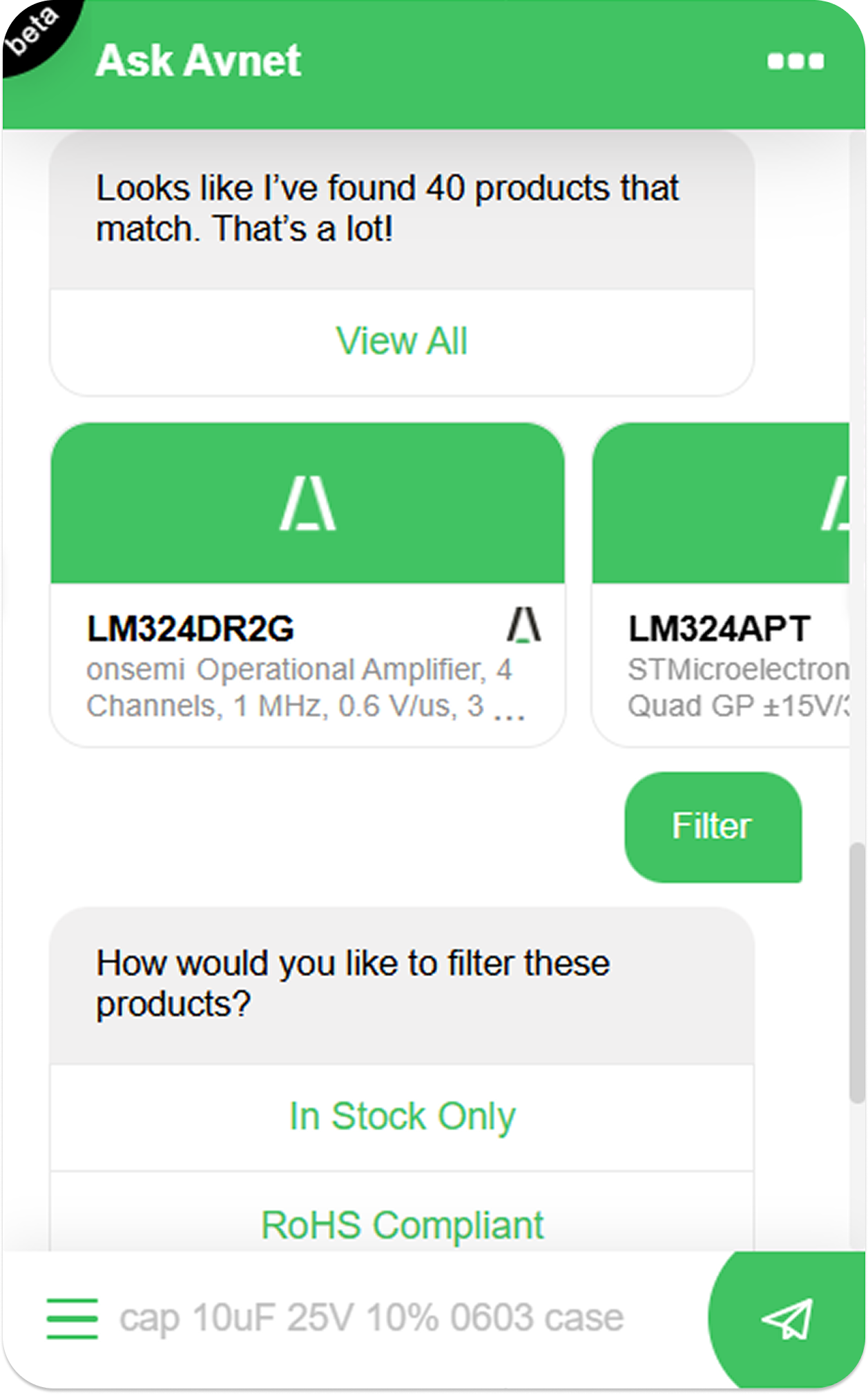

Iterated to offer 2-3 guided options (e.g., “Search parts,” “Check order”), reducing frustration. A consultant coached me on interviewing: let silence linger, avoid leading questions, note pain points (e.g., “Why no stock filter?”). We tested across age groups and roles, refining for clarity.

Trained Microsoft LUIS with rep phrases and user inputs, tweaking until QA hit a launch-ready accuracy (90%+ intent recognition).

Guided options added post-testing, easing navigation of 30,000+ daily line items.

4. Launch & Iteration

We launched the chatbot across Avnet’s site, targeting 100,000+ customers. I guided interns to craft a marketing campaign—emails, site banners—to alert employees and users. Early wins showed reps handling fewer routine calls from the thousands-strong backlog.

Post-MVP, we expanded features: enabled users to log into their accounts within the chatbot to view order information and history easily, reducing reliance on reps for status checks.

The team also added page detection to suggest alternatives/related parts when items weren’t available or users sought options (e.g., “Unfortunately there are no products available with those filters. Looks like I’ve found 7 products that can be used as an alternative”).

Additionally, we linked Element14 articles and Hackster projects—acquired platforms for maker communities—to inspire engineers and broaden reach.

New tabs opened seamlessly, chats persisted across pages, and users could email transcripts for reference.

Later features: Account login for order history and alternative part suggestions, plus maker resources from Element14/Hackster.

Results

Slashed customer service workload—previously dozens of calls and hundreds of emails/chats daily with a backlog in the thousands—by enabling self-service for part searches, order tracking, and account-based history access across a 5M+ part catalog.

Enhanced online engagement by offering account login for order visibility, suggesting alternatives (e.g., “Unfortunately there are no products available with those filters. Looks like I’ve found 7 products that can be used as an alternative”), and providing maker resources (Element14, Hackster), keeping users on-site despite stock gaps and driving transactions for 30,000+ daily line items.

Pioneered the industry’s first AI chatbot for semiconductor distribution, strengthening Avnet’s digital presence across 800+ suppliers and 400 locations while reaching maker communities.

Set the stage for future enhancements (e.g., returns, broader tool suggestions), proving the chatbot’s adaptability.

Reflections

What I Learned: User research uncovers hidden needs (e.g., guided flows over freedom); iteration turns rough prototypes into polished tools; simplicity wins with niche audiences.

Challenges Overcome: Convincing stakeholders to start small (MVP vs. all-in) and adapting to users who distrusted tech—solved with testing and guardrails.

What I’d Do Differently: Advocate for related-parts suggestions earlier to retain users faster; document flows real-time (a lesson for my UX journey!).

Skills Gained: Data analysis (Excel), flow design (Lucidchart), usability testing, and stakeholder alignment—now pillars of my UX practice.